Diagnostics Centre of Excellence

Cable diagnostics made easy

Many power utility companies already use cable diagnostics as they provide information on the condition of cable systems and therefore valuable information for

- condition-based maintenance

- planning replacement costs and

- enabling quality checks for new systems and following repairs.

Practical experience shows that if you use cable diagnostics, you can reduce the number of unplanned outages and often utilise cable systems for significantly longer than with a purely time-based replacement strategy. Network operators often save many thousands of euros per cable route within a matter of years.

There’s no need to fear cable diagnostics

But what is the best way to apply diagnostics? Which devices and software are required to maximise the benefits of diagnostics? The initially seemingly complex technology and the fact that there are no universal limit values for analysis can be unsettling, especially (but not only) for companies that want to introduce cable diagnostics. In order to avoid uncertainties when purchasing and using the technology and to maximise the benefits for operators, the team at the BAUR Diagnostics Centre of Excellence offers a number of services:

Initial consultation

Every network has its own characteristics – and the respective framework conditions and objectives can vary from network operator to network operator. A solution that is right for customer A may not necessarily be ideal for customer B. As part of the pre-sales consultation, the BAUR team works with you to determine which objectives you want to pursue and which cable systems (XLPE, PILC, mixed sections, age and condition) are preferred. The team then proposes suitable measurement technology on the basis of this information.

BAUR Solutions

Software solutions

The basic principles of cable diagnostics.

The proposed solutions usually have one thing in common. The technology should incorporate both of these methods so that diagnostics are as informative as possible:

Dissipation factor measurement (tan-δ or TD measurement),

which provides clear information on the condition of the entire cable insulation and its ageing (for medium- and long-term network maintenance planning) without endangering the cable

Partial discharge measurement (PD measurement)

detects faults in the cable, for example defects in joints and terminations as well as electrical trees

Partial discharge measurement is already commonplace among many network operators. However, when used alone, this method only offers limited informative value when it comes to assessing the condition. The results of all the diagnostics procedures combined provide a complete overview of the ageing condition of a cable.

To help your team perform the multitude of measurements rapidly and reliably, Baur devices offer standardised processes and the option to perform the dissipation factor and partial discharge measurements in a single operation. The Monitored Withstand Test goes one step further and combines the diagnostic measurements with cable testing. This way, cable diagnostics run almost effortlessly along the way. We can help you find the right hardware and software to achieve your goals.

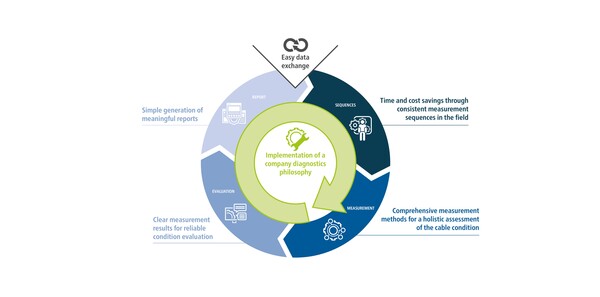

Develop a diagnostics strategy and evaluation logic

The diagnostics strategy and evaluation logic are developed in line with the network conditions and requirements, and are tailored to the distribution network. Strategy and logic should be defined at the beginning and can be adapted over time according to objectives and experience. Clear action plans that can be implemented by the company are defined. The BAUR team supports you with setting up the strategy and assessment rules, drawing on more than 20 years of experience in VLF diagnostic projects.

Device and software training

To ensure that you achieve reliable results, BAUR diagnostics devices work according to defined standards and offer standardised processes. But the technology in these devices can do far more: You can develop a customised diagnostics philosophy tailored to the network and adapted to the requirements of your selected diagnostics strategy. In addition, individual measurement sequences can be defined and transferred to other devices so that all measurement engineers perform the measurements in the same way and even less experienced personnel produce the results required for your analyses.

You can find out how to use the devices and the operating software and how to define measurement routines adapted to your network and your objectives in our training documents and films as well as in video calls and at on-site workshops hosted by our team at the Diagnostics Centre of Excellence. Benefit from over 20 years of experience and partnerships between BAUR and network operators around the world.

Software training for BAUR Software 4 and statex®

The best way to accumulate experience is to implement your individual strategy for measurements and analyses. This is where BAUR Software 4 steps in as a continuously updated software package for cable fault location, cable testing and cable diagnostics, as well as statex® software. Our team can show you the optimal way to use the software so that you can develop your own routines and gain valuable experience.

BAUR Software 4

Along with a range of features, BAUR Software 4 offers the following tools for efficient diagnostics:

- defined and standardised measurement sequences

- customised measurement sequences that can be stored

- automated measurements and result evaluation

- measurement sequence transfers to other devices

- easy initial assessment of the results using smileys

- generation of informative reports for management and engineers

- adaptation of reports to company-specific requirements

- easy data transfers to asset management

The values and reports recorded by BAUR Software 4 offer various analysis options: You can analyse individual measurements, compare measurements of similar cables, identify trends in multiple measurements on the same cable, and much more.

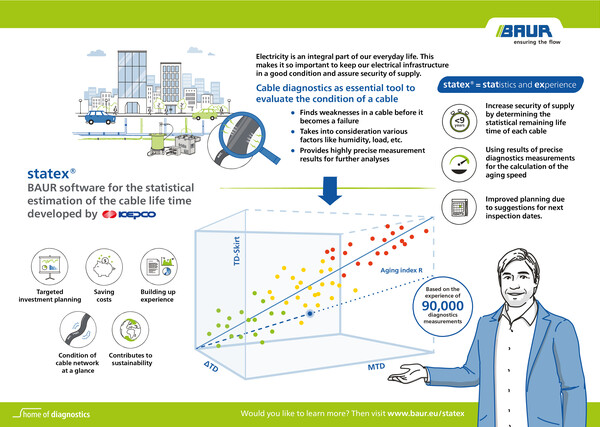

statex®

Our statex® software solution, developed in collaboration with the Korean network operator KEPCO, provides even more options for analysing tan δ measurements. This analysis software evaluates the measurement data and calculates the remaining life time of cables using a patented algorithm. The software draws on a large data pool containing the measurement results of plastic-insulated and paper-insulated cables, as well as mixed sections. Evaluation with statex® enables a significantly more precise assessment of the cable condition and often leads to a longer remaining cable life time than, for example, an evaluation according to IEEE criteria. The statex® results also provide recommendations on when the next cable diagnostics should take place, or when maintenance work or cable replacement need to be scheduled.

This avoids unnecessary measurements that would put additional strain on the cable without reducing the reliability of supply.

Continuous improvement of diagnostics

Cable diagnostics are most effective when performed strategically and over a long period of time. On the one hand, this means that the condition of all relevant cable routes – for example, those that are critical to the system or potentially in a dangerous situation – can be examined little by little. On the other hand, repeat measurements are also possible, which permits trend analyses. Repeat measurements also improve the remaining life time calculation by statex® and provide even more accurate results.

The interaction between the expertise of technical specialists at the power utility firms and reliable statistical analysis using statex® software is the key to lasting success here.

The strategy and objectives should be regularly scrutinised and adapted to the corresponding requirements. The team at the BAUR Diagnostics Centre of Excellence is on hand to help and advise you on these topics. After all, if there’s one thing we’ve learned: Lasting relationships and cooperation are crucial for progress.

Detailed information on cable testing and diagnostic