The future begins with innovation

Trendsetting BAUR solutions

With their know-how, BAUR employees are esteemed members of official bodies, which means that they are quick to learn about new trends and developments. Working together with our customers, we develop and create new products and solutions of the highest quality, thereby ensuring the long-term success of the company.

Areas of innovation

Innovations in cable testing and diagnostics

Information about the cable condition enables the network operator to identify weak points in cables and makes it possible to plan investments. Our direct and regular contact with customers allows us to learn about market requirements at an early stage. With decades of experience and the extensive expertise we have gained as a result, we are able to realise new trends as they arise and play an important role in ensuring the security of supply of power grids.

truesinus®

The voltage generation technology invented in 1990 and patented in 1994 by BAUR is currently the only feasible basis for all types of measurements on underground cables. It permits the least destructive cable testing and condition evaluation of medium-voltage cables in compliance with VDE, IEC and IEEE. Only the truesinus® technology provides a precise basis for meaningful and reproducible cable tests or condition evaluations with dissipation factor or partial discharge measurements. And this even for simultaneous measurements, e.g. with MWT or full MWT.

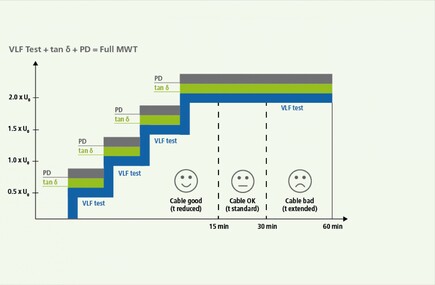

MWT

MWT or Full MWT stands for Monitored Withstand Test and combines dissipation factor measurement with partial discharge measurement. Both diagnostics procedures have their own advantages and provide valuable additional information, ensuring greater accuracy during condition evaluation. This combination saves time and is recognised by official bodies such as the IEEE and IEC.

Integrated dissipation factor measurement in the VLF generator

One of BAUR's core strengths is to take large and heavy measuring devices and transform them into light, compact, and practical solutions. The revolutionary frida device, including precise dissipation factor measurement, was developed in record time. Unlike other voltage shapes, the VLF truesinus® voltage is load-independent, symmetrical and continuous. This is the prerequisite for high precision as well as the reproducibility and comparability of measurement results. In some countries, measurement engineers even refer to the VLF method as the "frida test".

Innovations in cable fault location

When faults occur in cables, the top priority is to locate them. Speed and precision are critical to ensuring that the cable can be put back into operation in a timely manner. Our mission is ensuring the flow – we develop new methods and devices to achieve this worldwide.

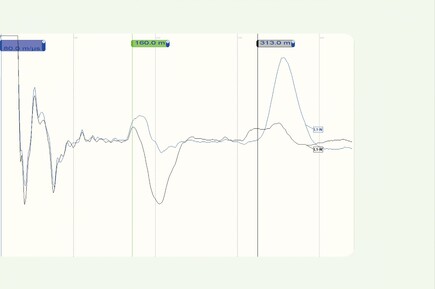

SIM / MIM

SIM/MIM, the most well-established and precise cable fault pre-location method, was invented and introduced by BAUR in 1999. The particular advantages of this method are its simple, universal application and clear interpretation of echograms. Faults are reliably detected with only a single HV pulse but several measurements, and are automatically evaluated and saved.

XL-CFL

Submarine power cables are indispensable for reliable power supply. The protracted downtime of these cables translates into losses in the millions for the cable operator – with the downtime costs growing day on day. The innovative XL-CFL system from BAUR provides solutions that are specifically designed for effective and precise cable fault location on long submarine and land cables.

Innovations in cable test vans and systems

Equipped to handle any call-out. This was the original objective of our customers and paved the way for the development of our first cable test van in the late 1960s. Numerous optimisations and further developments have allowed us to proudly include an automatic, software-controlled cable test van and state-of-the-art software in our current product portfolio.

Cable test van transcable

The late 1960s saw the development of the first delivery van equipped with BAUR products. This milestone achievement provides a fast and easy way for cable testers to get their equipment where they need it. transcable is an automatic or semi-automatic, single- or three-phase cable fault location system. Through the modular design, the individually functional modules work independently from one another. This means that the transcable system can be easily extended at any time.

titron

The titron® automatic measurement and test system is characterised by efficient technology and intuitive operation. The new generation high-performance system is based on state-of-the-art technology and provides efficient, safe and reliable cable fault location, cable testing and cable diagnostics with its software support. It provides network operators with extensive knowledge about cable condition and gives them an edge in troubleshooting and fault prevention. Failures and unscheduled repairs can be avoided, affording certainty in maintenance planning.

BAUR Software 4

The BAUR Software 4 combines all the solutions for cable fault location, cable testing, and cable diagnostics. Cable fault location includes well-established measurement methods as well as innovative approaches such as Conditioning-SIM/MIM, enabling faster and more effective localisation of wet cable faults that are difficult to locate.

When it comes to diagnostics, asset management also benefits from standardised sequences for professional and reproducible condition evaluation of electrical equipment. This makes it possible to devise maintenance and replacement strategies and prioritise specific measures. At the same time, the automated sequences and integrated combination of methods minimise the time required to carry out diagnostics on site.

Innovations in insulating oil testing

BAUR revolutionised the market for insulating oil testers in the 1950s and has been the preferred company for insulating oil testing internationally for more than 60 years. We work with universities, laboratories, and standardisation and test bodies to advance the testing of insulating materials and the associated standards. The expertise acquired over the last six decades in the development of our insulating oil testers has been incorporated into national and international standards, which today define the industry standard.

DTL C

The DTL C, the world's first device of its type, was developed together with Swiss company Methrom. The DTL C is still the leading standard in insulating material testing worldwide. The dissipation factor can be calculated in several ways using the programmable DTL C. In practice, the comprehensive analysis with the DTL C enables extremely precise and therefore more economic maintenance planning. The saving potential for network operators depending on the network size and the associated insulating oil requirement is several hundred thousand Euros per year.